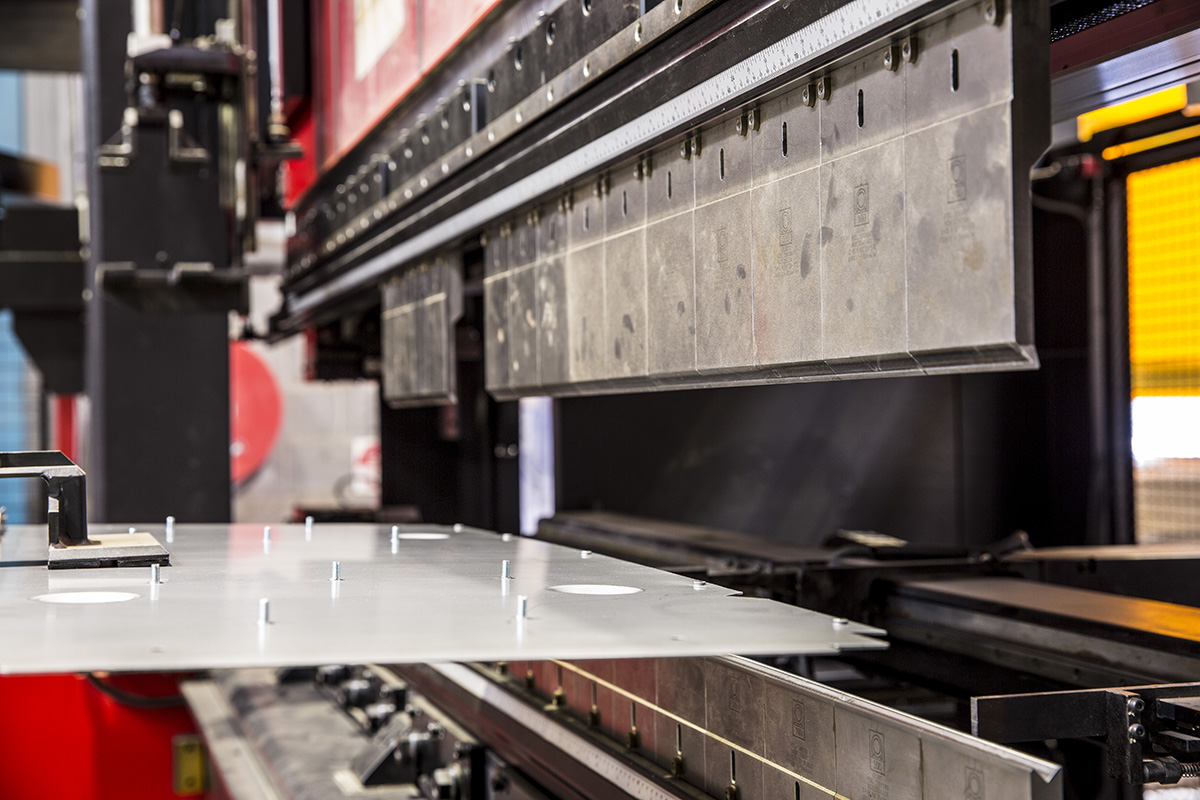

Sheet metal folding with fully automated, or semi-automated solutions

Complex folds are handled with ease

It’s extraordinary what components can be fabricated and manufactured using sheet metal. A large radius bend, for example, isn’t a design feature that many people would think possible with sheet metal. Yet FORM2000's automated folding machines can achieve this with ease.

Typically, the single greatest time-cost component of the sheet metal manufacturing process is the folding operation. We work with our customers to develop the most cost-effective production solution based on requirement, accommodating both low and high production volumes through adapting fully automated, or semi-automated processes.

Our large investment in a range of leading-edge automated and robotic folding equipment from AMADA, provides us with the flexibility to optimise process selection to accommodate your end requirement – based on volume, sheet metal size, gauge and cost.

Our fully automated robotic solution offers significant benefits in our sheet metal folding factory when compared to traditional forming processes, including:

- Outstanding bending quality

- Exceptional precision and accuracy

- Short setup times due to the automated tool changer

- Simple programming and a high degree of operational convenience

- Enhanced multi-staging capabilities

- Low energy consumption

The system is particularly suited to large volume orders of sheet metal fabrication.

OUR EQUIPMENT

- AMADA CB 83 x2

- AMADA TBZ 2523H Automatic Panel Bender

- AMADA HDS 8025NT x3

- AMADA HDS 1030N

- AMADA Astro 100NT HDS1030 x2