Specialising in OEM sheet metal component supply

FORM2000 provides advanced sheet metal manufacturing specialising in OEM component supply to manufacturers who seek an outsourced supply chain solution. We value our customers and do not compete in the end-user consumer market.

| Concept development | Early design collaboration services to assist customers in developing fabricated sheet metal component fabrication to suit their end-product. Consulting with FORM2000 from the beginning ensures the full capabilities of our automated sheet metal manufacturing processes can be incorporated into your design. |

| Engineering | On agreement of rough concepts and specifications, FORM2000 provides 3D CAD drafting to engineer the sheet metal product component and to determine manufacturing feasibility, best process and machine selection and near final costings. |

| Prototyping | We can provide accurate pre-production sheet metal product prototypes for further evaluation, design refinement and for you to test during your manufacturing process. |

| Build to your specification | Already have a fully working design? We can take it from there and simply manufacture your sheet metal product. FORM2000 will assess your specifications and provide costings. If we can identify cost savings through minor design modifications we’ll put them to you for consideration. |

| Outsourced processes | FORM2000 offer ease and flexibility as your single source sheet metal provider sheet metal fabrication equipment is in-house but we work with selected sub-contractors for special processes such as printing and machining. |

Facilities & Capabilities of our Melbourne Factory

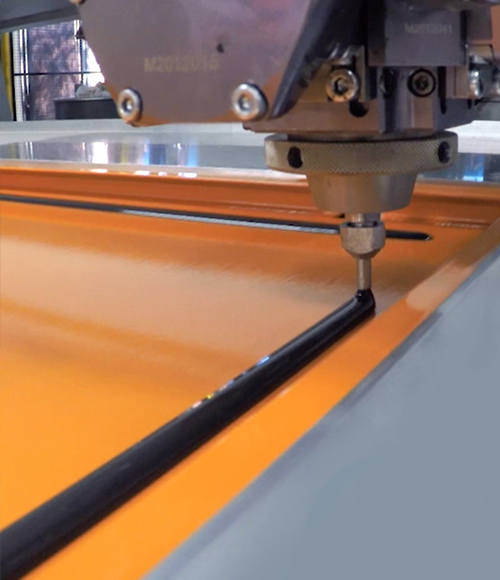

FORM2000's comprehensive set of services integrate cutting-edge sheet metal fabrication equipment with a workforce of qualified manufacturing engineers, technicians and welders capable of transforming a concept into a well-priced, high quality end sheet metal product.

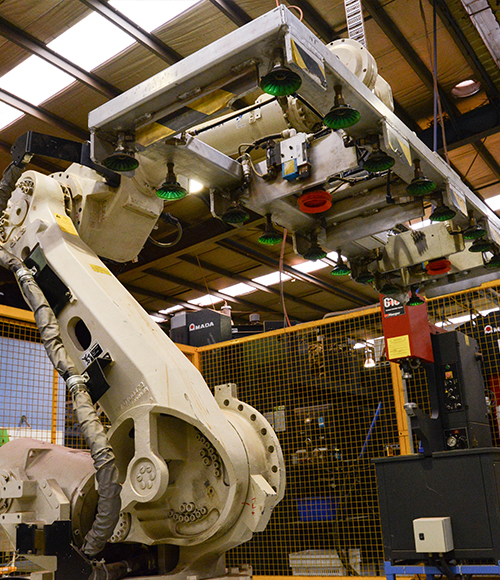

We have heavily invested in new, up-to-date sheet metal fabrication machinery, including automated machinery supplied by leading global robotic sheet metal machinery vendor – AMADA – housed within our 7,000 sqm manufacturing facility located in Melbourne.

FORM2000's facilities and equipment are specifically purposed to support a high mix, low volume capability, whilst ensuring high consistency and repeatability, and enabling us to meet our customers’ just-in-time sheet metal inventory requirements.